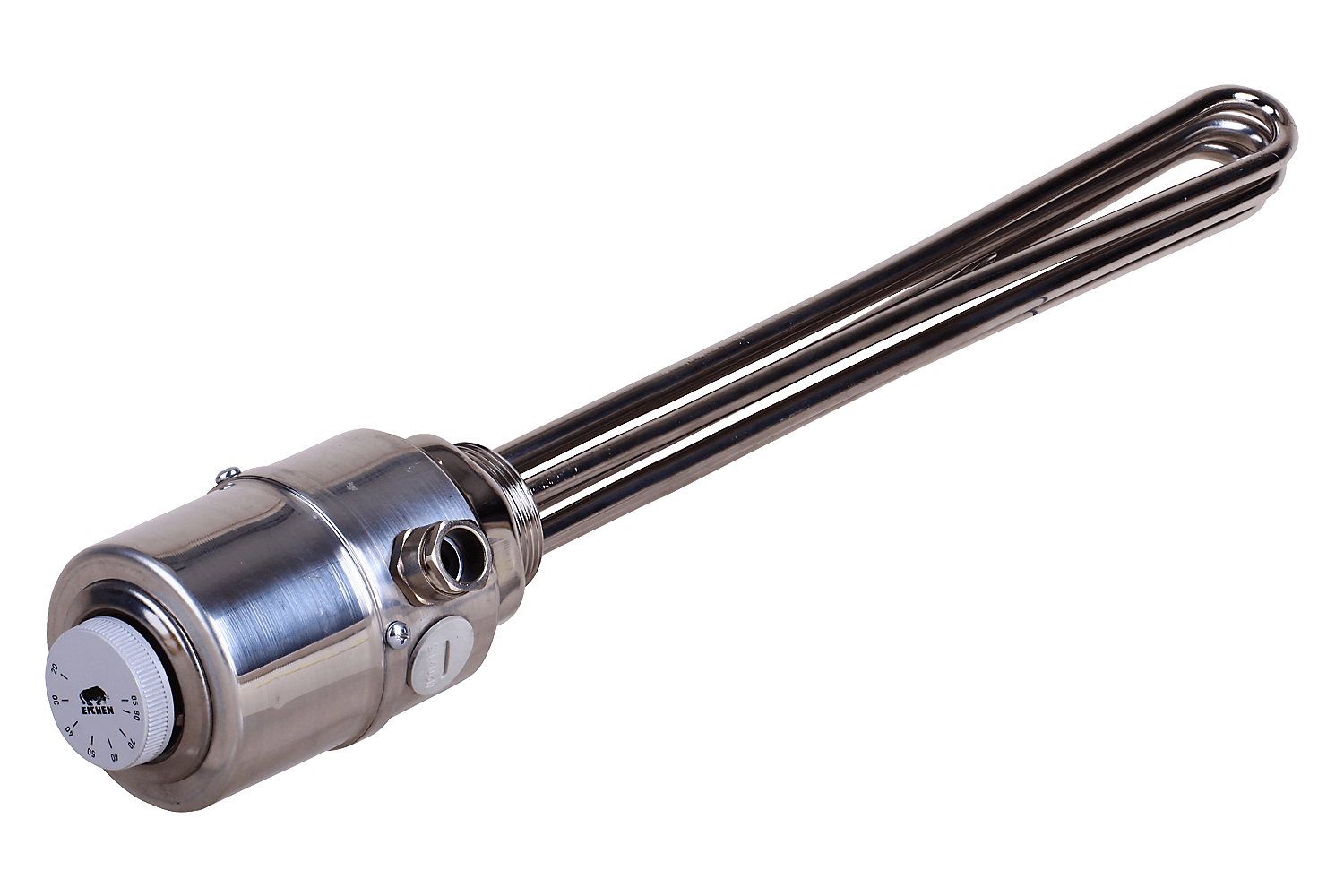

Immersion Heater Installation Immersion Heater Installation

Installation Guidelines

Note: Eichenauer thoroughly tests our heaters to exceed the specifications required by Underwriters Laboratories and other safety agencies. Nonetheless, electricity and electric heaters have inherent safety concerns that must be addressed. Installation and maintenance of heaters and electrical equipment should only be performed by qualified technicians or electricians in accorance with the National Electric Code (NEC) and any relevant local codes, regulations and guidelines. It is the responsibility of the user to ensure that a suitable heater is used and that it is installed correctly in the appliance, machine, boiler or other application and that suitable controls & safety devices are installed and operating correctly. This document is only a guideline. Follow the boiler OEM's procedures and specifications when available.

Disconnect the appliance from the electric supply at the fuse panel or main disconnect. Follow proper lockout/tagout procedures according to OSHA safety guidelines. If replacing a heater that is already installed, close the water supply valve, release pressure and drain the water tank. Disconnect heater lead wires and label them if needed for re-installation.

Before installation, insulation resistance of heaters should be checked with a 500VDC 'Megger' (Megohm meter). This is to check for possible moisture absorption during shipping or storage. In the event that the Megger value is less than 20MΩ, the heater must be dried before use.

The mounting surface must be clean & free of surface defects in the gasket area. Clean the flange of all foreign material; including old gasket material. Install a new gasket each time that the heater is changed. Remove any mineral deposits on the inside of the water tank, taking care not to damage the vessel. Install heater and tighten mounting bolts. Mounting bolts or studs should be of appropriate strength and torqued properly (22 ft-lbs for 5/16-18 bolts).

Attach electical lead wires to approprate terminals of heater following wiring diagram and torque specifications on drawings. Poor quality electical connections will cause localized overheating of the terminals and busses and lead to premature failure and possible fire hazzard.

Open the water supply valve and allow tank to fill completey. Verify that there are no water leaks around the mounting flange and that all safety devices are operational and in place. Only after these verifications are complete, can the supply power be re-connected. Allow the device to operate for a normal use cycle and again verify that there are no leaks.

After 2 or 3 normal operation cycles, we recommend that all mounting bolts and electical connections be re-checked for proper torque settings. Disconnect and lockout the electical supply when doing so.